Classification of Lithium Polymer Batteries

Lithium polymer batteries can be divided into three distinct categories:

-

Solid Polymer Electrolyte Lithium-Ion Batteries: These batteries utilize a mixture of polymer and salt as the electrolyte. With low ionic conductivity at room temperature, they are best suited for high-temperature environments.

-

Gel Polymer Electrolyte Lithium-Ion Batteries: By incorporating plasticizers and additives into the solid polymer electrolyte, these batteries enhance ionic conductivity, making them viable for room-temperature use.

-

Lithium-Ion Batteries with Polymer Cathode Materials: Featuring conductive polymers as cathode materials, these batteries offer three times the specific energy of traditional lithium-ion batteries, positioning them as the latest generation in this technology.

Compared to liquid lithium-ion batteries, polymer lithium-ion batteries benefit from solid electrolytes, enabling thinner profiles, customizable areas, and flexible shapes. They also mitigate safety risks such as leakage, combustion, and explosions. The use of aluminum-plastic composite film for casings boosts specific capacity, while employing polymers as cathode materials can increase mass-specific energy by over 50%. Additionally, these batteries exhibit improved working voltage and charge-discharge cycle life, earning them the reputation as the next generation of lithium-ion batteries.

Principle of Lithium Polymer Batteries

Lithium-ion batteries are categorized into two types: liquid lithium-ion batteries (LIB) and polymer lithium-ion batteries (PLIB). Liquid lithium-ion batteries are secondary batteries where Li+ intercalation compounds serve as both the positive and negative electrodes. The positive electrode typically employs lithium compounds such as LiCoO2, LiNiO2, or LiMn2O4, while the negative electrode uses a lithium-carbon intercalation compound (LixC6). A typical system is represented as:

-

(-) C | LiPF6—EC+DEC | LiCoO2 (+)

The electrochemical reactions are as follows:

-

Positive electrode reaction: LiCoO2 = Li1-xCoO2 + xLi+ + xe- (2.1)

-

Negative electrode reaction: 6C + xLi+ + xe- = LixC6 (2.2)

-

Overall battery reaction: LiCoO2 + 6C = Li1-xCoO2 + LixC6 (2.3)

The principle of polymer lithium-ion batteries mirrors that of liquid lithium batteries, with the key difference lying in the electrolyte. The battery’s core components—positive electrode, negative electrode, and electrolyte—include at least one or more elements made from polymer materials. Currently, polymer materials are predominantly used in the positive electrode and electrolyte. The positive electrode may consist of conductive polymers or inorganic compounds typical of lithium-ion batteries, while the electrolyte can be a solid or colloidal polymer electrolyte or an organic electrolyte. Unlike traditional lithium-ion technology, which relies on liquid or colloidal electrolytes requiring robust secondary packaging to contain flammable components (thus adding weight and limiting flexibility), polymer lithium-ion technology eliminates excess electrolyte. This enhances stability and reduces risks from overcharging, collisions, damage, or overuse.

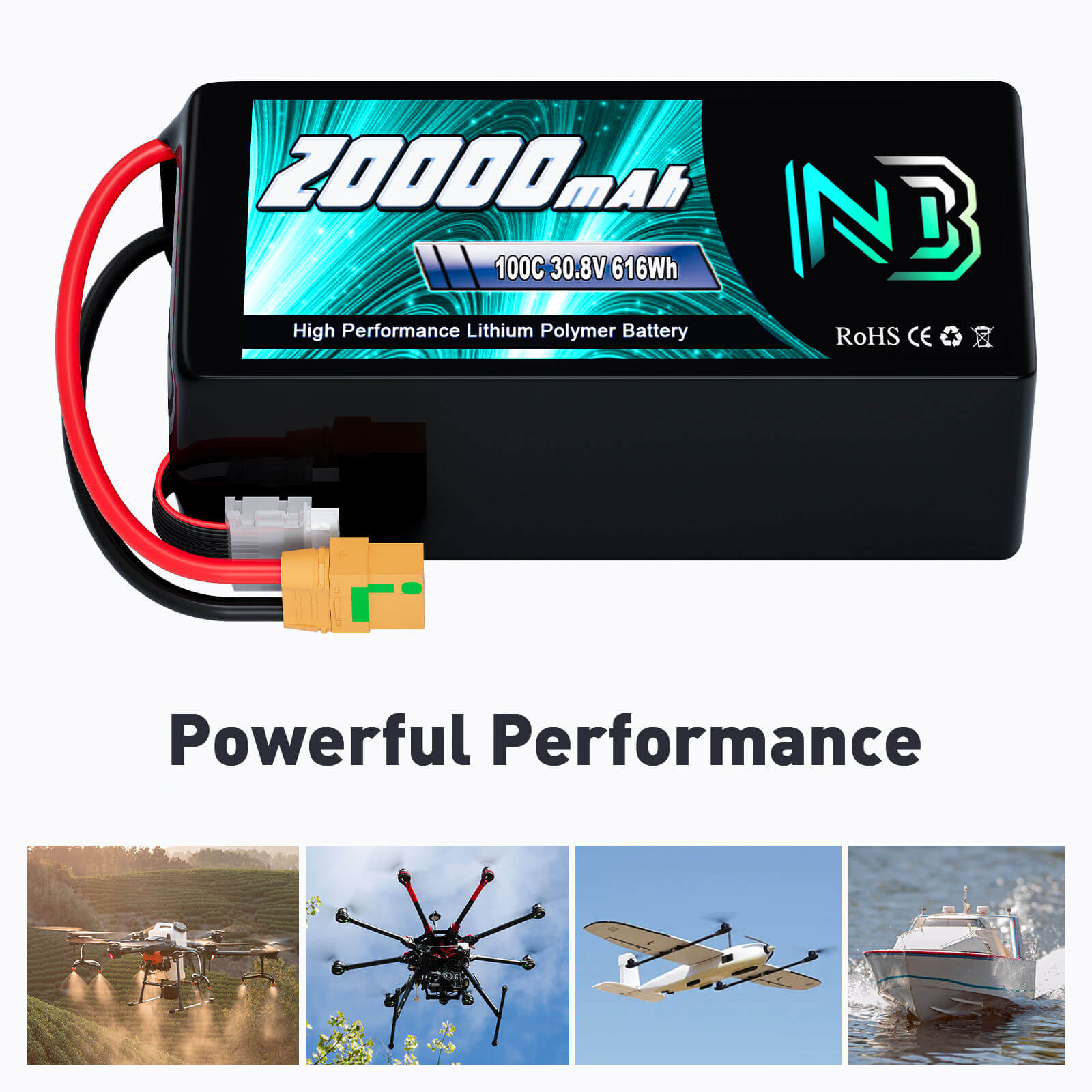

Applications of Lithium Polymer Batteries

With their higher energy density, lithium polymer batteries provide extended power supply durations. In the mobile communications market, laptops and smartphones are the primary consumers, driving advancements in battery technology and production. Mobile phone suppliers are focusing on developing high-tech lithium-ion batteries, particularly prismatic and cylindrical designs. The adoption of gel electrolytes supports the trend toward thinner batteries, catering to ultra-thin applications like smart cards, while improved lithium-ion protection circuits enhance safety. Primarily used in mobile devices, lithium polymer batteries are steadily replacing nickel-cadmium batteries due to their numerous advantages.

Development of Lithium Polymer Batteries

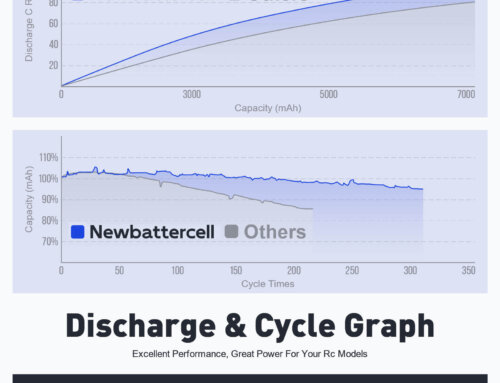

The new generation of polymer lithium-ion batteries offers remarkable design flexibility, achieving thicknesses as low as 0.5 mm (e.g., ATL batteries, equivalent to a card’s thickness), along with customizable sizes and shapes. This adaptability allows manufacturers to create batteries tailored to specific shapes and capacities, optimizing product performance for developers. The unit energy of these batteries is 50% higher than that of current lithium-ion batteries, with significant improvements in capacity, charge-discharge characteristics, safety, operating temperature range, cycle life (exceeding 500 cycles), and environmental performance.