Drone Battery Safety System Requirements

Market Growth and Safety Challenges

The number of drones in the market continues to rise. The U.S. Federal Aviation Administration projects sustained strong growth in aerial imaging and data collection products, including applications in emergency rescue operations. However, all drones are susceptible to failures, leading to various issues. Battery malfunctions, such as catching fire during charging or failing during flight, highlight a range of electrical problems, underscoring the importance of robust electrical protection systems. An increasing number of tools and technologies are available for implementing battery safety systems and electrostatic discharge (ESD) protection.

Figure -1 illustrates a generic drone design, highlighting key areas where drone manufacturers must consider circuit protection for various electrical subsystems, along with the most common circuit protection components for each application.

Figure 1: Drone Subsystems Requiring Circuit Protection

Protecting Batteries and Charging Circuits

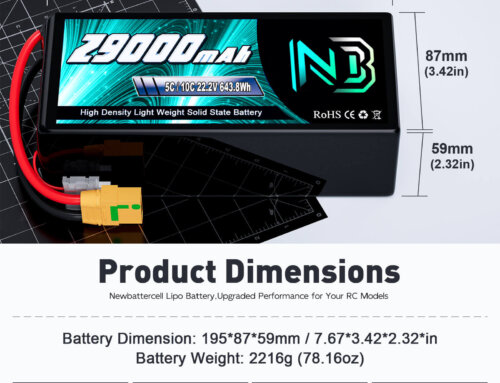

Drones rely on onboard batteries to power their operations. Lithium polymer (LiPo) batteries are among the most commonly used due to their advantages:

-

High Energy Density: Relative to their size and weight, LiPo batteries offer superior energy storage.

-

Higher Voltage per Cell: This reduces the number of cells needed to power onboard systems compared to other rechargeable batteries.

-

Slower Discharge Rate: LiPo batteries retain their charge longer when not in use.

However, improper charging or usage can degrade LiPo battery performance, potentially leading to smoking or fires. Two externally induced events that can cause issues with lithium-ion batteries are over-discharge and overcharge:

-

Over-Discharge: If the battery voltage drops below approximately 1.5V, the anode may release gas. When the voltage falls below 1V, copper in the current collector dissolves, causing an internal short circuit. This necessitates undervoltage protection, typically provided by a battery protection IC.

-

Overcharge: When the battery voltage reaches around 4.6V, gas and heat buildup occur at the cathode. While cylindrical batteries have internal pressure protection, such as Current Interrupt Devices (CID) and Positive Temperature Coefficient (PTC) disks (which increase resistance with heat), LiPo batteries lack internal CID and PTC mechanisms, requiring external overvoltage and overcurrent protection.

Circuit Protection Options

Several circuit protection options safeguard drone batteries from overcurrent and overheating conditions, including:

-

Metal Hybrid PPTC with Thermal Activation (MHP-TA): Combines low thermal cutoff temperature, high hold current ratings, and compact size, making it ideal for protecting LiPo batteries. The latest MHP-TA devices offer a 9VDC rating and higher current ratings than typical battery Thermal Cutoff (TCO) devices, capable of handling the voltages and charge rates common in high-capacity LiPo batteries.

-

PolySwitch PPTC Devices: Suitable for lithium-ion (Li-Ion), nickel-metal hydride (NiMH), or nickel-cadmium (NiCd) batteries. These resettable devices are compatible with high-volume electronics assembly and hold UL, CSA, and TÜV certifications, simplifying compliance with regulatory requirements. Their low resistance extends battery runtime and enhances protection against thermal events.

-

POLYFUSE LoRho Surface-Mount Resettable PPTC: Designed for lithium-ion and LiPo battery protection circuit modules, these devices offer fast overcurrent and overtemperature protection with ultra-low internal resistance, voltage drop, and power consumption. Their automatic reset feature provides a low-maintenance alternative to one-time fuses for overcurrent protection. As surface-mount components, they can be integrated into electronic protection modules on circuit boards, simplifying assembly.

-

Surface-Mount Fuses: Unlike PPTC devices, traditional fuses stop current flow entirely upon tripping, which may be desirable in critical applications but requires replacement after each event. PPTC devices, being resettable, allow continued operation after most overcurrent events unless extreme conditions occur.

Conclusion

Effective battery safety systems are critical for ensuring the reliability and safety of drones. By implementing robust circuit protection components like MHP-TA devices, PolySwitch PPTC, LoRho PPTC, and surface-mount fuses, manufacturers can protect LiPo and other battery types from overcurrent, overvoltage, and overtemperature risks, enhancing drone performance and safety in various applications.